Chain link fence is and has been one of the most popular styles of fence for both residential and commercial fencing projects. The fence consists of steel tubing used as a top rail connecting to steel posts on the side. This is called the frame or framework of the fence and is held together by rail clamps and topped with post caps. Inside the fence frame, a wire mesh made of individual metal strands woven together to create the diamond pattern, sometimes called the fabric, is hung and stretched between the two end posts.

The other components, like the clamps and top caps, are called the fittings. Those fittings connect and cap off the fence as well as attach the fabric mesh to that framework.

Due to the affordability and versatility of chain link fences, it is often chosen to fence in residential yards. Businesses looking to add security to their lot also often use chain link due to its relatively low cost, low maintenance, and ease of customizing its configuration to the land. Since the fencing and components can be purchased in any quantity, it is easy to configure any fence based on height, color, grade, and length.

Some common terms you should be aware of:

As previously mentioned, chain link fence is a common choice for residential and commerce fencing projects. This is simply because of its many different applications.

Residentially, chain link adds perimeter security to a property securing children and pets to the designated area. The fence also adds security in keeping people out while not blocking visibility through the mesh so unwanted visitors will be easily seen. Building codes also require that fencing be installed for swimming pools and other uses, and chain link meets those code requirements.

For commercial use and construction applications, chain link is a very common and versatile option. The fence is easily installed and customized to any shape and size needed for the job. It can be used on projects as small as dumpster enclosures and large as huge construction projects. Even large facilities like airports and factories use chain link fences both for perimeter security and internal security.

When higher security is needed for places such as manufacturing facilities and prisons, chain link fencing is topped off with barbed wire arms and barbed wiring. This works to deter potential intruders and make it difficult to get over the fence. This is a cost effect and physically effective way to add security to a property.

There is also an option to temporarily block off non-permanent chain link fence sections or temporarily secure certain sections or areas. These are often used indoors when a new renovation happens or on a temporary work site where a permanent fence is unnecessary.

A common question a lot of potential installers ask is, what heights do chain link fences come in? Chain link fence comes in many heights and can be configured in any desired length. Because the components, framework, and mesh can all be purchased piecemeal, the length and shape of the fence have endless possibilities.

Many manufacturers offer different heights, starting as small as 3' (three feet) tall, and can sometimes make a custom height of 20' (twenty feet) tall. Standard sizes for the fencing usually come in 1' (one-foot) increments until it reaches the height of 8' (eight feet), where it then increases in 2' (two-foot) increments.

Most fencing manufacturers can make custom heights for different project configurations. Custom orders usually involve more steps and a longer lead time in the process. Typically, customer orders come at a minimum total linear footage or amount. Make sure to call your fencing supplier to talk to a salesperson who will help you figure out what will best suit your needs.

A typical chain link comes in a silver or grey-looking color. Most people associate this original and traditional-looking fence with chain link. The steel tubing and mesh on this fence are just standard steel galvanized to help prevent rust and other weather degradation.

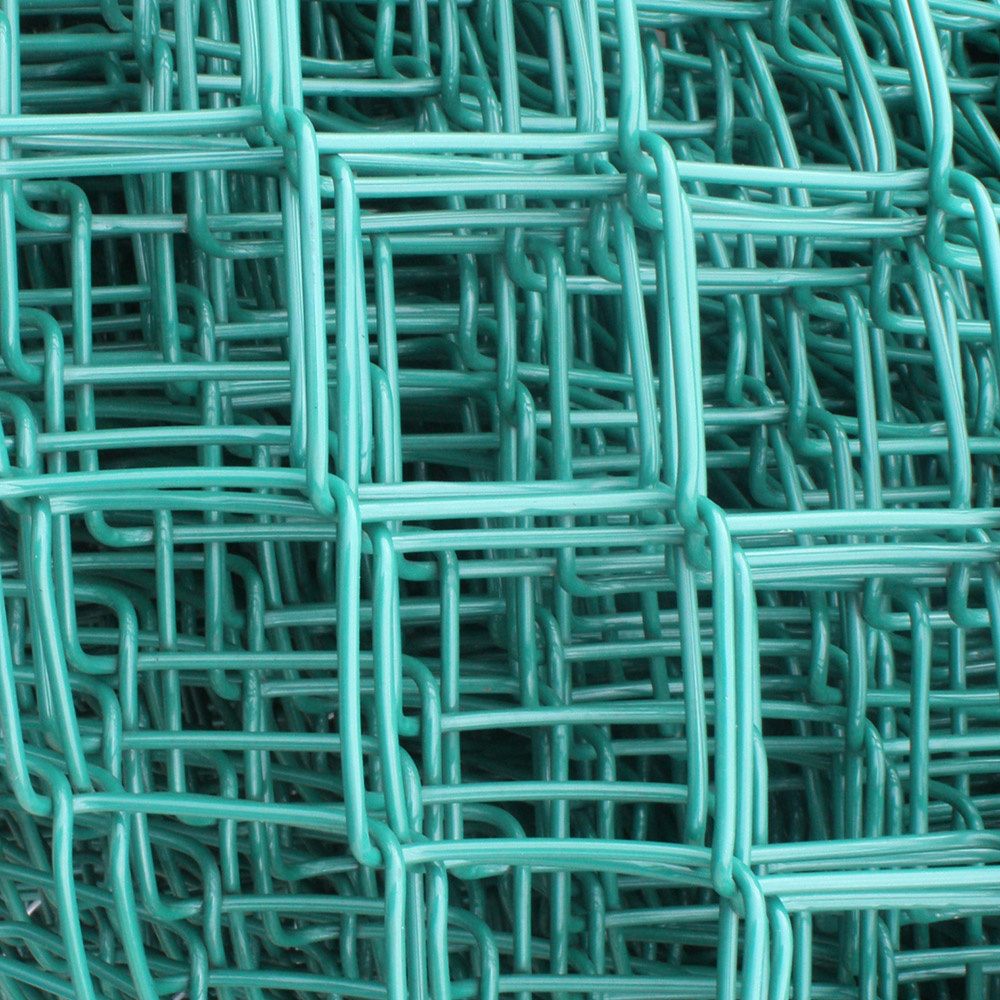

However, chain link fencing is now available in different colors. It is now possible to purchase chain link fence mesh and its components in brown, white, green, and black, quickly becoming the new favorite. Just like using different heights, these colors will come with some additional cost due to the extra steps in the process they must undertake.

That grey or silver color typical on steel fencing comes from the coating that covers the base metal. That coating is zinc coated through a galvanization process. Galvanized is the most common and popular coating type. The covering helps to protect against rusting and any other form of degradation from the weather.

Like with other exposed metals, the metal would oxidize when exposed to the elements without the galvanized coating. Eventually, it would start to rust out and fall apart. That process is greatly slowed by adding zinc. The galvanized coating will also oxidize when exposed to the elements. However, unlike uncoated or raw steel, it won't rust but will rather have the shiny surface begin to fade and turn into a dullish grey color.

When there are special requirements for the fencing, sometimes galvanized coatings don't meet those requirements. In this instance, the fence installation company will choose to go with an aluminized coasting, an alternative the manufacturer offers. Most people cannot tell them apart from galvanized fences because they share a similar look. However, aluminized will differ because it is more resistant to temperature fluctuation and abrasion. This does come at a higher price point.

Aluminized coatings are often used in areas where they may be exposed to chemicals in the air. Those chemicals can cause faster erosion in chain link that is not aluminized. One commonly seen example is where there is a chain link fence next to a roadway that experiences winter conditions. The salt or chemical spray makes aluminized fence a better choice to stand up to time.

Sometimes, a homeowner or business owner does not like the old industrial look of that silver fence in their yard or around their property. Therefore, manufacturers offer different color options for those customers. These colored options are darker than the original Silver and blend in with their surroundings far better. They are more eye-pleasing and create a more minimal look. They still have the original components as steel but are coated in either vinyl or a powder coat.

These two types of coating, vinyl and powder coat, offer a similar look but provide different benefits. They both will provide a rubber-like smooth texture to the finish. It will also help the fence to hold up better to the elements, especially with temperature fluctuation during season changes. They will be priced higher than a traditionally styled galvanized fence, but the vinyl coating will still be less than the powder coated. This is because the powder coating is far more durable of a coating.

Many customers opt to use a different colored coated mesh or fabric while still using the galvanized framework. This will help to change the overall look but keep costs down.

Chain link fence comes in different grades. In general, there are three different grades, residential grade, industrial grade, and industrial grade.

What is it that makes them different grades? Well, that grade is largely determined by two different components. The first is the gauge, or the thickness, of the wire, used to make the mesh fabric. The next is the size of the framework or the pipe tubing used. This referenced size also includes the diameter and the wall thickness of the pipe used.

Chain link fabric, the diamond-shaped woven steel, sometimes called mesh, is offered in different gauges. The individual wire thickness is what is used to determine the gauge. The smaller the gauge number, the thicker, heavier, and stronger the wire mesh. For example, an 8 gauge wire is stronger than a 12 gauge wire mesh but will be heavier.

Residential fences typically have a wire fabric gauge of between 9 gauge and 11.5 gauge. Commercial-grade fencing projects typically use 8 to 9-gauge wire fabric. Industrial chain link fence most often uses a 9 gauge wire but occasionally uses a heavier chain link like the very thick and strong 6 gauge.

The fencing fabric, or the mesh, also comes in different sizes. This size is determined by the space measured between each link. The most common sized mesh is around 2 inches; however, many other sizes are available.

For certain projects, small mesh, often called mini mesh, is available when a finer woven pattern is needed. This is common in dog kennels, tennis courts, and other applications where a stronger, tighter mesh is needed with less possibility that anything can pass through it. Like the idea behind chain mail, the smaller the diamond, the tighter the weaver and the stronger the mesh.

Many customers will ask, does pipe size matter? Can't you use any pipe to make the frame of the fence? The simple answer is yes. The size of the pipe matters. Only three parts make up the framework part of a fence. The first part is the terminal post, consisting of the corner, end, and gate posts. The next is the lined post which is all the intermediate posts installed between the terminal posts. Last are the top rails, the pipes running horizontally at the fence's top.

Occasionally, a bottom rail is installed to provide extra security and durability. This is not typically common on residential projects. The different components of the framework are offered and can be purchased in different diameters and wall thicknesses. , the larger the diameter, the stronger the framework will be. The wall thickness of the framework also determines its overall strength. Again, the thicker the wall, the stronger the frame.

Chain link fencing framework is configured in many different diameters. The top rail diameters are 1 3/8 inches and 1 5/8 inches. Residential projects normally use the smaller top rails around 1 3/8 inches on fences up to 5 feet tall. Taller or commercial and industrial fence projects typically use pipe diameters of 1 5/8 inches.

The line posts are the posts that fall between the terminal or end posts. Usually set 10 feet or less on center, they provide a solid point of attachment to tie the chain link fabric to and hold the top rail in place. Residential fencing projects typically have line post diameters of around 1 5/8 inches and 2 inches. Commercial and Industrial projects typically have a line post size of 2 inches, 2 3/8 inches, and occasionally 3 inches in diameter. The latter provides extra strength for taller projects.

The terminal post will be the largest diameter post in the framework. This post holds the fabric's tension along with the top rail's help. Gate posts are also considered terminal posts. Typically, the gate post is the same size as the other terminal posts on residential jobs. However, the gate posts usually have a larger diameter on commercial and industrial projects.

Residential chain link projects typically have a terminal post diameter of 1 7/8 to 2 3/8 inches. Commercial and industrial jobs typically use a terminal post with a diameter of 2 3/8 to 2 7/8 inches. Gate post diameters depend on how wide and tall the gate leaf is. The typical standard diameter for walk gates and smaller double gate openings on commercial and industrial jobs is 2 7/8 inches. When a double gate spans a distance wider than 10 feet, a 4-inch diameter gate post is common. 6 5/8 or 8 5/8-inch wall posts are used for the widest gate openings.

Large-diameter posts help stop a gate post from sagging or feeling springy due to the weight of the gate that it is holding up.

The wall thickness of the fence frame affects the grade and the fence's strength. The three most commonly used and seen thicknesses are .065 thousandths, 20 weight, and 40 weight. Residential fencing jobs typically use the .065 thousandths thickness measurement. It provides adequate strength while keeping costs down. Commercial fencing projects typically use the SS20, or 20-weight, framework. SS20 or 20 weight is stronger than the residential .065 but not as heavy as the 40 weight. It offers good strength at a mid-tier price.

Industrial fencing uses SS40 framework or 40 weight. It is the heaviest and strongest option but is also the costliest. Although, if the projects are not too large, the cost difference between SS20 and SS40 is fairly small. Most clients will use the 40-weight, heavier, thicker pipe for their commercial and industrial chain link fences. It offers maximum strength and longevity. Factories, baseball fields, and prisons are the most common places you will see this weight of chain link pipes.

| Residential Grade | Commercial Grade | Industrial Grade | |

|---|---|---|---|

| Line Post Diameter | 1-5/8″ – 2″ Diameter | 2″ – 2-3/8″ Diameter | 2-3/8″ – 3″ Diameter |

| Terminal Post Diameter | 2″ – 2-3/8″ Diameter | 2-3/8″ – 3″ Diameter | 3″ – 4″ Diameter |

| Post Wall Thickness | .065 thousandths | SS20 | SS40 or Schedule 40 |

Often, when installing a chain link fence, you will also need to install a gate. Gate entries allow entry and exit to and from the fenced-in area. The type and width determine the width of the gate's opening.

Chain link gates can be built in practically any width. Walk gates are comprised of just a single panel called a gate leaf. The common widths for walk gates are 3, 4, 5, and 6 feet wide. Any opening larger than 6 feet wide requires double gates.

Double gates use two different gate leaves, the single gate panels, to cover the wider width of that gate opening. A center post between the two gate leaf panels is not required. One of the leaves will have a sliding rod that enters the ground to keep it stationary. This is known as the drop rod or cane bolt. Typically, one-half of that gate will be used as the main gate. However, when more access is needed, the drop rod can be pulled out of the ground, and the second gate leaf can be pulled open.

Double gates are great for gaining access to larger equipment or trucks or when there is a plan for future expansion or construction. Double gates are also commonly used to cross over a driveway.

For commercial and industrial fencing installations, it can be common to see double gate openings that span a distance up to 30 feet wide. With those large distances, the customer must also consider the space needed for each gate to open. Other options suit their needs if there is not enough open space for a swing gate. Cantilever gates are sliding gates that roll on a rail parallel to the fence. The thing to remember, though, is that cantilever gates must be one and a half times the size of the gate opening. This extra length accounts for the counterbalance of the game to keep it from dragging on the ground.

Cantilever gates work well and are used in both industrial applications. They are best suited for installation jobs where limited space or a large span needs to be covered.

Some other options and extra features can be added to a chain link fence. Typically, these extras are used only for industrial or commercial jobs.

Barbed wire is simply a strand of wire with small sharp pieces tied to it to create the barbs. The small, clipped wire is tied on at various increments. It is typically installed with three strands facing one side of the fence, usually outward. The wire is angled at a 45-degree angle set by the barb arm or points vertically straight up.

The barbed arm is a part that includes a cap on the bottom to close the pipe hole and has an arm extending out that holds the barbed wire. These barbed wire arms add roughly one-foot extra height to the fence.

When additional security is important for the fencing job, a six-strand barb arm is available. This arm adds three barbed wire stands to the fence's inside and outside. The six-strand variety is most commonly used at prisons, military facilities, or recycling centers.

Due to its effectiveness, affordability, and low maintenance, chain link fencing appeals to many customers, especially when compared to wood or vinyl. But if privacy is the goal, chain link favors visibility over cover. So how can you add privacy to a chain link fence?

Privacy slats are commonly used to add privacy to a chain link fence. These slats are small strips that weave in between the links of the fabric. While originally made of aluminum, these strips are now primarily vinyl and easy to weave in by hand.

Standard privacy slats offer roughly 75% coverage, while a winged variation offers around 95% coverage. There is also the option to use hedge privacy slats which are strips of privacy slats that are disguised as being covered in leaves to make the entire fence appear to be a bush.

People also use privacy screening to add privacy to a chain link fence. Although it is not as durable as a privacy slat, it is easier to install and more cost-effective.

Privacy screening is available in a semi-transparent and an opaque screen. Thanks to modern printing technologies, these screens can be printed with signs, advertising, logos, or slogans, turning any chain link fence into a billboard. This practice is common at sporting facilities like baseball and football fields.

Privacy screening is susceptible to damage and abuse from the wind and elements. It is also recommended to be removed during the winter when the climate turns a bit harsher. Due to the weather damage, it is recommended that the screen be replaced every few years. It is considered to be a more temporary solution.

The installation process for chain link is fairly simple, and the method is the same regardless of the height of the fencing project. However, depending on your geographical location, the method of installation may vary slightly based on different procedures. Here are the basic steps.

Every single fence installation must begin with setting the posts. Chain link fence installation is no different and begins in the same way. There are, however, a few differences.

In the Northeast, all installed posts are concerted for the chain link fence installation. Frost levels help to determine how deep the posts should be set. Occasionally, cities or towns have their requirements that must be followed.

As a general rule, 24 inches deep is the minimum recommended depth. The contractor will often set the depth at 36 inches for extra strength. As previously mentioned, some cities may require 42 inches of depth and also will require an inspector to approve the depth before filling the hole with concrete. This process is called post-hole inspection.

In southern climates, only the terminal posts are set in the concrete. Line posts will be driven using a pneumatic driver or hand. The installation method varies based on the job's region and climate. Regardless of where though, the posts must go in first.

In the next step, you will need to connect a top rail after the posts are set and leveled. Installation of the top rail is easy and quick but must be done before the mesh is hung. Typically, it will come in 21-foot lengths and rests on top-of-the-line posts by using a guide called a loop cap.

When the top rail reaches the end of the fence or a gate, it will connect to the terminal post using a post or chain link fitting. This connector has several names, so be sure you use the correct one for your application.

There are several ways to stretch the fabric once the framework is completely built. Even dedicated fence installation tools help you hand, hold, and stretch the mesh to fill the void in the frame. The mesh is attached to the terminal post by using connectors or fittings. Fence ties are then finally applied to hold the fence upright.

The last step in the installation process would be to hang the gates to access the area. Most installs will have at least one gate to install, but often, there are multiple, including double gates.

The gates hang between two set terminal posts. On a single-leaf walking gate, one of the terminal posts will act as the hinge post, and the other will act as a latching post. Double swing gates require both terminal posts to act as hinge posts.

There are many different configurations for hinges and latches for chain link gates. Male and female hinges and fork latches are the most commonly used components. After the gates are hung, the fence installation is complete.